Complete project management in one tool

User report from BURGER ENGINEERING GmbH & Co. KG

Projektron BCS has enabled us to move our entire project management into a single tool. It is particularly practical for us that in the course of project planning in BCS, a quotation is also created automatically. This allows us to provide our customers with a transparent statement of the project costs at any time - even during the course of the project. Projektron BCS has fully met our expectations - also with regard to the product promise that the tool can be adapted to a wide variety of challenges and requirements.

BURGER ENGINEERING - Developing success with cross-industry know-how

BURGER ENGINEERING GmbH & Co. KG is a leading provider of solutions in the fields of drive technology, digital electronics, fieldbus and communication technology, power electronics and individual power supplies.

We have been offering services and products in the field of electronics since 1986. We develop concepts as well as electronics, hardware, firmware and software for well-known manufacturers in the medical technology, aviation and industrial automation sectors as well as in the automotive and consumer electronics industries. Our experienced team, rooted in the company for many years, offers support in all phases of product development - from prototype construction to series introduction.

Our portfolio of services includes innovative systems engineering as well as support with required approvals or with the preparation of circuit diagrams and layouts. In addition, BURGER ENGINEERING has a certified quality management system according to ISO 9001 and ISO 13485.

From technology-driven start-ups to classic German medium-sized companies with their hidden champions and global corporations - they are all among our satisfied customers. Among the best known are prominent players such as VW, Siemens or Airbus.

BURGER ENGINEERING currently consists of about 60 employees at the company headquarters in Schwaig near Nuremberg and is a company of the BURGER GROUP, one of the leading system partners in the field of customer-specific drive technology.

Purely project-based work

BURGER ENGINEERING is an electronics development service provider and works entirely on a project basis. Each year, BURGER engineers complete between fifty and one hundred projects for client companies.

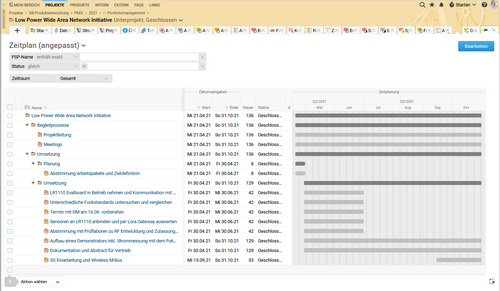

The project flow at a glance:

- Customer inquiry about a project idea

- Project plan preparation and first effort estimation

- Detailed planning for the preparation of a quotation

- Assignment and project start

- Development of requirements specification with subsequent start of the implementation phase

- Test and validation phase

All project phases can be easily and clearly mapped in Projektron BCS.

Depending on the project and customer requirements, BURGER ENGINEERING employees develop according to the V-model, Scrum or a mixture of both. Work is primarily carried out according to classic project management methods if hardware components or an electronics sample are involved. Pure software development projects are usually implemented based on Scrum. All projects are mapped in Projektron BCS and shared among the project participants.

As a rule, around four to six BURGER ENGINEERING employees work together on a project for the development of a hardware component of a larger device. Project durations vary considerably, ranging from a few months to two years - depending on the complexity and the specific customer requirements.

The reason for this is the broad BURGER ENGINEERING service portfolio, which ranges from support with the layout design of a circuit diagram to the development of a complete product, from the idea through several development loops to support with certification. And this also in regulated environments such as safety and security or even in A-Spice projects in the automotive industry.

Jörg Klenke himself works in the project management office. Five BURGER ENGINEERING employees take on the function of project managers here, so that several projects are being handled in parallel at any given time. As the technical head, each project team also includes a systems engineer. While the project manager is more responsible for the organizational side of a project and customer communication, the system engineer is in charge of the technical implementation.

Depending on the specific requirements of the project, the project teams are completed by testers, technicians, software developers, hardware developers or FuSI engineers.

Without Projektron BCS as a powerful and open-method project management software, the current project flow would not be feasible. Internally, we also maintain a project management manual as a guideline for our project management activities. Thanks to BCS, we have already been able to automate many of the processes defined there.

Projektron BCS fully covers requirements

Since 2014, all projects at BURGER ENGINEERING have been mapped in Projektron BCS, the project development documented and finally the overall project evaluated. The introduction of the Projektron solution was preceded by a comprehensive exploration of the vendor market for project management software, in which BCS was able to convince the BURGER ENGINEERING team.

Subsequently, the tool was subjected to an in-depth evaluation by various employees. At that time, a cloud-based software was sought to replace the desktop office solution MS Project, which had been used to plan and manage BURGER ENGINEERING projects up to that point.

An alternative to the legacy system had become necessary because BURGER ENGINEERING required greater depth in detailed planning. Before the BCS implementation, task planning, effort planning, and the direct option for creating quotations did not mesh as seamlessly as the BURGER ENGINEERING managers would have liked.

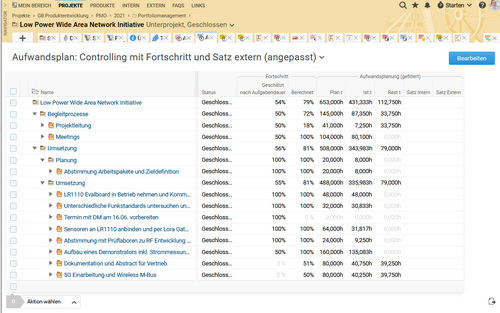

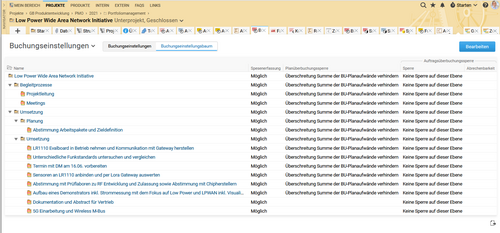

The possibility of transferring directly from project-related expense postings to invoicing was also not available. Last but not least, clean project controlling was only possible with the introduction of the Projektron solution. And as a nice side effect, the time recording of the employees including Time-off-account and the better cross-company vacation planning is seen.

However, the most important requirement on the part of BURGER ENGINEERING was the possibility of integrating external customers into project planning and the associated controlling. Complete project planning was also to be carried out in the new project management tool. And since at BURGER ENGINEERING projects are mainly billed on a time-and-materials basis within the framework of service contracts, the immediate posting of effort to the respective tasks, as well as the associated tracking, represented a further central selection criterion. Today, BURGER ENGINEERING employees book their working hours and their efforts for the individual project tasks directly in BCS.

In this way, the project manager and PMO can transparently view the planned and actual status at any time. BURGER ENGINEERING is a development service provider. Therefore, no project is like the other, each process has to be adapted to the specific requirements of the respective customer.

For these individual plans, it is very important that a wide range of options, tools and views are available to those responsible in the project planning phase. This was a point to which particular importance was attached when selecting suitable project management software. In addition, the new solution should be scalable with a view to later growth of the company.

From Quotation to Invoice - Our Entire Project Management in BCS

When BCS was introduced in 2014, the BURGER ENGINEERING project team began using all of the project management functions, quotation creation, invoicing and time tracking at the same time to replace the previous system as seamlessly and smoothly as possible. Before BCS was introduced, efforts were only recorded in Excel and transferred from there to billing. The options for recording hours and even minutes were not available, but this opened up completely new possibilities for BURGER ENGINEERING. In the meantime, BCS has been established for a long time and is used daily by all project participants.

Thanks to effort tracking, BCS is an excellent tool for BURGER ENGINEERING PMO to budget both external and internal tasks. It also provides an overview of how much effort goes into which tasks at any given time. During the course of the project, BURGER ENGINEERING employees regularly compare the actual and remaining effort with the planned effort. In this way, any need for action is identified at an early stage and those responsible can seek discussions with the customer in order to identify the causes of any additional expenditure and take appropriate countermeasures.

BCS offers BURGER ENGINEERING the maximum flexibility to clearly compile exactly the key figures that are currently relevant in the project overview. Thanks to the graphic visualizations in the form of traffic lights or tachometers, nothing escapes the attention of those involved in the project. Each employee can see at a glance whether he or she is on schedule with the processing of a task and can provide feedback via the option of estimating the remaining effort.

BCS not only provides more transparency during project execution and for internal BURGER ENGINEERING project controlling, but also during the planning phase vis-à-vis the customer: Even the first rough planning can be shared with the customer via BCS. In this way, the entire procedure and also the estimated efforts and budgets become more comprehensible for BURGER ENGINEERING customers.

If a customer also wants regular insight into the status of project progress and bookings during project execution, this is no problem at all. Especially with regard to this transparency towards the customer, BURGER ENGINEERING project manager Jörg Klenke can explicitly recommend Projektron BCS to other companies in our industry for project management.

In the BIRT report designer, the BURGER ENGINEERING project management team - after appropriate training by Projektron - has also designed its own project profile and project status report. Furthermore, BURGER ENGINEERING had additional controlling evaluations programmed by Projektron - for evaluating the rate of paid hours of our employees.

In addition, the BURGER ENGINEERING project management team created various checklists for the area of occupational safety as well as for the various quality gates in the projects.

Projektron BCS keeps its product promise

BURGER ENGINEERING is very satisfied with Projektron BCS because the solution covers all the requirements of everyday BURGER ENGINEERING project work. Yet not all of the software's functions have been fully exploited, such as the capacity planning options in BCS. And other modules, such as the integrated CRM, are currently not being used at all. Currently in the test phase at BURGER ENGINEERING are the BCS functionalities for capacity planning in the resource management module. Soon it will be decided whether and in which way they can be made usable for the BURGER ENGINEERING team.

At first, BCS does not seem particularly intuitive to use in some places. But at BURGER ENGINEERING, even new employees who had no previous experience with project management and project management software are able to work independently and reliably with BCS after brief instruction and independent practice.

This year, several BURGER ENGINEERING employees also attended an expert training at Projektron GmbH, where they were made aware of some functions of BCS modules that are not yet fully used by BURGER ENGINEERING. In this way, the quotation and order process within BCS could once again be significantly optimized. Based on this experience, it is now planned to attend the BCS training courses again at regular intervals of one or two years at the most.

Employees of BURGER ENGINEERING have also attended special training courses on the topics of project controlling, project management according to Scrum in BCS and reporting in recent years in order to be able to make the best possible use of the software's possibilities.

Conclusion

Projektron has lived up to its product promise and has grown well with the size of the company. The BURGER ENGINEERING employees have always been able to adapt the solution to changing circumstances - partly on their own and partly with the support of the Projektron team. If the BURGER ENGINEERING team has suggestions for optimizing or expanding views and functionalities, they are simply submitted as a ticket. In this way, not only BURGER ENGINEERING benefits from an always optimal project management solution, but also Projektron. Because BCS continues to develop in this way. To the benefit of all users.