BCS - Good usability and customisability

Success story from Kendrion Automotive

Projektron BCS is in daily use at almost all Kendrion Automotive sites. Kendrion Automotive accounts for approximately 50% of the turnover and employees of Kendrion N.V.. We develop and produce software, hardware and mechanics according to automotive standards and norms such as IATF or Automotive SPICE. In addition to the standard views in Projektron BCS, some views were created at our request. We like the fact that we can make configurations ourselves to a certain extent. Whereas the projects were initially managed exclusively by the project manager, several people are now involved in the planning and customisation of the sub-projects.

Kendrion - pioneer and innovator

Kendrion develops, manufactures and supplies intelligent actuators that help drive the global push towards electrification and sustainable energy. Today, our compact and connected actuators can be found in wind power, robots, factory automation, electric vehicles, power distribution and industrial heating processes, where they support our OEM customers around the world in the transition to safe and clean forms of energy.

As a technology pioneer and innovator building on over 100 years of experience, we are driven by the desire to find creative solutions to the technical challenges of tomorrow. We take full responsibility for the way we source, manufacture and do business. Sustainable business practices are integrated into our processes and embedded in our culture. With roots in Germany, headquarters in the Netherlands and listed on the Amsterdam Stock Exchange, our presence extends across Europe to the Americas and Asia.

Closer collaboration through standardised project management software

In the course of product development with our OEM and Tier 1 customers in the automotive industry, project management software is essential for controlling projects, also with regard to compliance with norms and standards such as IATF or Automotive SPICE. In particular, the growing requirements in software development and the associated maturity level validations make a project management tool that meets the requirements essential.

Before using Projektron BCS, Kendrion Automotive used various project management software solutions, which was due in particular to the acquisition of several locations. These were selected to suit the respective product area (software/hardware and mechanical products).

In the course of closer cooperation between the previously independent development sites, the need arose to use standardised project management software. This project management software was to map the different requirements of the various Kendrion Automotive products.

Implementation of Projektron BCS

As part of the selection process at Kendrion, eight project management software providers were compared in a selection process. Based on the requirements from the different product areas of software, hardware and mechanics, a short list was drawn up in the first step, in which Projektron BCS prevailed over the competitors and was implemented at Kendrion Automotive.

Projektron BCS impressed us above all with its good usability and simple customisability. The ability to easily book employee hours for individual projects and tasks was also an important requirement for us in order to create a reliable basis for good project controlling. The informative overviews for employees, projects and the Muti Project Cockpit were further arguments in favour of using Projektron BCS.

We found major gaps in the fulfilment of requirements for software development in the automotive industry. Document management and the options for "baselining" project content could not be mapped in the Projektron BCS standard. Together with Projektron, these topics were discussed in workshops in preparation for the introduction of Projektron BCS at Kendrion Automotive and solutions were developed.

For the introduction, several workshops were held with those responsible from the various product areas and the Projektron contacts. The implementation of our requirements was discussed in the workshops and necessary adjustments to the tool were realised. The introduction focussed on the "Projects" area with project planning and recording of required hours.

The initial aim was to establish the tool in project management worldwide, to achieve reliable feedback on hours and, in a second step, to implement tool-based resource planning, which is often described as the supreme discipline in project management.

In use every day and everywhere - Projektron BCS

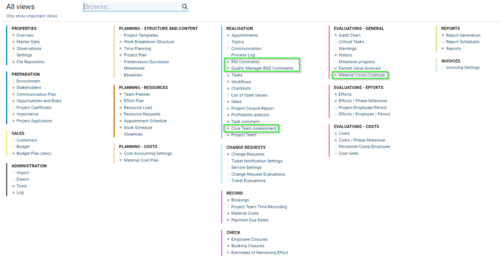

In the meantime, Projektron BCS has become well established at Kendrion Automotive and is used daily at almost all locations. In addition to the aforementioned project planning and resource management, the tool is used for regular project reporting (individual and multi-project reporting), monitoring project budgets and for change management. The feedback of hours in daily or weekly bookings is now routine for our colleagues.

In addition to the views available as standard, some views were created at our request. We like the fact that we can carry out configurations independently to a certain extent.

An interface to our ERP system was created so that we can maintain an overall commercial overview. On the one hand, newly generated project numbers are automatically transferred from BCS to the ERP system and, on the other hand, created orders and booked invoices are imported into BCS. In addition to analysing and monitoring hours, this also enables us to track investments and other project costs.

For change management, we have used the ticket system to define a workflow that covers various process steps from analysing the change to making the decision and implementing the change. The functionalities of the ticket system are very helpful in ensuring a smooth and complete process flow.

We are also happy to use the Open Points functionalities to record and track important smaller issues in the project. We like to send the created open points by e-mail so that the responsible persons receive a reminder in their e-mail inbox. We have configured a new "Send button" with the function of sending the last comment by e-mail in addition to the name of the open item.

Documentation of meetings or agreements is usually recorded in the minutes.

We are currently working on making greater use of opportunity and risk management in order to have even more project-relevant data available in one place. The risk charts are already an integral part of our gate presentations.

In addition, we are currently working very intensively on the introduction of the "Products" workspace in order to support the agile approach in our development projects in the best possible way. The introduction of new ticket types in the tool is also being discussed in this context. As mentioned above, the ticket system is currently being used for change management and has been customised for our needs in this context.

Conclusion and outlook

Although the tool has now been established in the company for several years, we currently have an increased need for customisation in Projektron BCS due to the changes in the automotive industry and the associated changes in our own process world, which also entails an increased need for training.

While projects were initially managed exclusively by the project manager, several people are now involved in planning and adapting sub-projects independently. This requires a revision of the authorisation concept as well as training courses for the people involved. Comprehensive documentation is also more important than ever to ensure the best possible coordination between the teams.

In this context, we would like to see further work on an intuitive and clear interface, particularly in the "Products" area, in order to optimise collaboration between agile teams.