Meaningful schedules and high agility

Success story from TechnoWood AG

Projektron BCS is our tool for the on-time production of our plants. This means we can always give our customers meaningful and reliable deadlines. We are very happy that we made the switch to BCS.

Our vision - The highest art of customised process solutions in wood

We are an international manufacturer and supplier of machines and software in the wood industry with 60 employees. We combine the following three core competences under one roof: Timber, machine and control engineering.

Our headquarters are nestled between the mighty Säntis and the unique mountain range of the Churfirsten in Alt St. Johann in Switzerland.

TechnoWood AG was founded in 1992 by Urs Steinmann. In the founding years, we concentrated mainly on programming ISO code for 5-axis CNC machines. In addition, connections to CAD/CAM systems were programmed. Building on this core competence, we developed further branches. Via control construction for upgrading existing CNC systems and equipping new systems, the path led to the development and construction of our own CNC machines.

Thanks to innovation, dedication and team spirit, as well as the excellent work of those involved in the timber construction industry over the past few years, we have been able to grow steadily and continue to do so. Together with existing and newly acquired customers, we have continued to develop. We are therefore ready for the future and its challenges.

Planning boards no longer do justice to project management

Due to the constant growth of the company and the high demand, the requirements for the planning of our projects and their production also increased. The previous planning method using classic planning boards on the wall was no longer suitable and we aimed for a higher level of detail.

Contact and introduction of Projektron BCS

The first contact with the Projektron BCS customer consultant was very pleasant and courteous. It was always a good cooperation, from the evaluation to the introduction and support. In a joint workshop, all the basic settings and structures were worked out.

At the beginning, we concentrated on taking over the existing projects and only in a second phase did the production and service staff also start working with BCS.

When introducing project management software, it is important to allow enough time for the changeover. This was a big challenge for us, as everything happened alongside our usual working day.

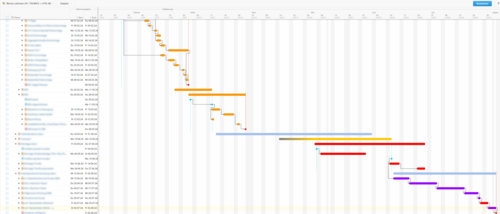

BCS enables reliable scheduling

We use BSC for the scheduling of the complete project execution. This also includes the internal and external work in production and service. BCS is our tool for on-time production of our plants, so that we can always provide the customer with meaningful and reliable deadlines.

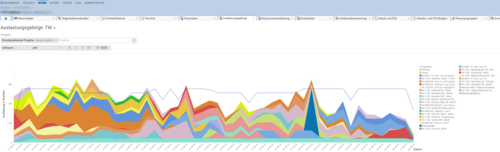

Decisive for this is the schedule or project plan in BCS as well as the corresponding resource utilisation. We therefore also use BCS for work planning and for the associated time recording.

Tapping further potential

We are very happy that we made the switch to BCS. Today we have much more meaningful schedules and can respond to changes from suppliers and customers more agilely and, above all, earlier.

In the future, we would like to further increase the detail of planning, among other things by introducing workflows and checklists in BCS.